Filtration of Extra Virgin Olive Oil

The oil as it is produced from the olive mill contains some residual substances, like some remains of the olive pulp and some moisture.

The oil is edible, even with these residuals, but filtration improves the durability of olive oil (retains its quality characteristics for longer time) and also its appearance, as the oil before filtration has a cloudy look and after it is crystal clear.

This filtration is performed either by means of mixing the oil with an inert filtering aid (usually powder of diatomous earth) that has no interaction with the oil and then pass the oil through a pressure leaf filter, meaning filtering the foreign material through a cake formed by the filter aid on the filter leaves. The filtering aid together with the residuals we want to filter is then disposed and the oil comes out from the filter clear.

A typical pressure leaf filter is shown in picture bellow:

A final step of polishing filtration is then performed, passing the oil through food grade filter paper, to eliminate residuals of moisture and potential traces of filtering aid.

A typical filter papers press:

This filtration process is very common and is typically used for other liquid foodstuff, like wine and beer in other factories.

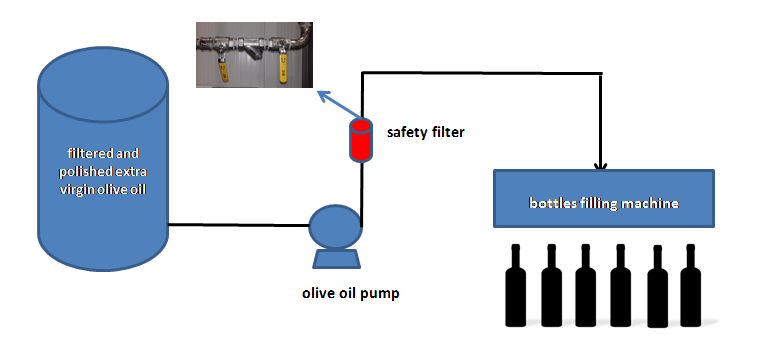

A final step of filtration is performed just before bottling and consists actually of safety filtration in order to make 100% sure that no remains from previous steps are going to enter the final product packaging. This step is performed by means of a fine mesh filter (mesh <2mm) which is mounted inside the oil pipe just before the filling machine. The filter is checked for integrity before every lot is produced. Look scheme bellow: